PT KARSA JAYA KARYA operates a factory located at Jl. Kampung KB Pasenan, Desa Pancoran Raya, Kec. Bondowoso, Kab. Bondowoso, East Java, with a warehouse located at Jl. Indrapura No.247, Perak Timur, Kec. Pabean Cantikan, Surabaya, Kota Surabaya, East Java. The company specializes in producing wood charcoal for barbeque applications, with minimum size 5 cm.

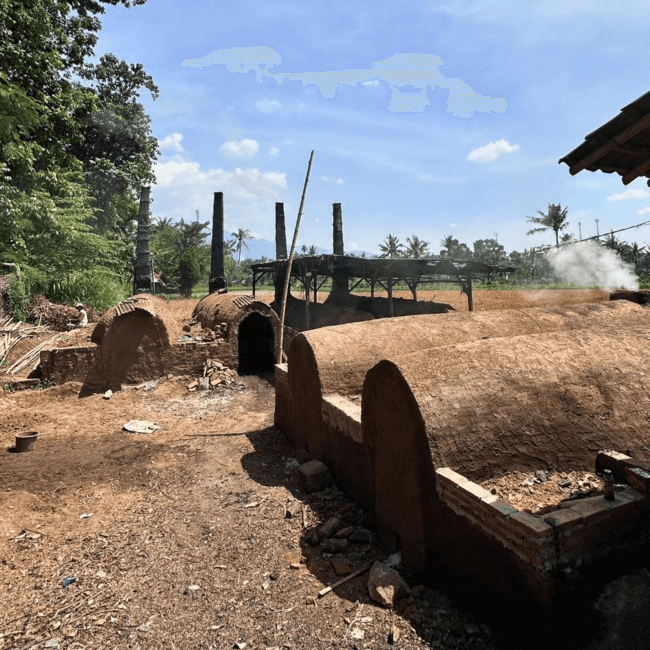

Our factory utilizes sustainable wood sources to create environmentally friendly products that meet industry standards. We specialize in producing charcoal, and our production is up to 160 tons Per month and has 6 kiln.

Our mission is to provide the world with top-quality, eco-friendly wood charcoal while contributing to environmental sustainability. We are committed to offering our clients a reliable supply of premium charcoal made from responsibly sourced materials.